Mining and Extracting Copper: A Detailed Process

Copper, a versatile and widely-used metal, plays a crucial role in various industries. From its extraction as ore to its refinement for market use, the process of mining and processing copper is complex and requires multiple stages to ensure the production of high-quality copper products. Let’s take a closer look at the journey of copper from the ground to the market.

1. Exploration and Mining

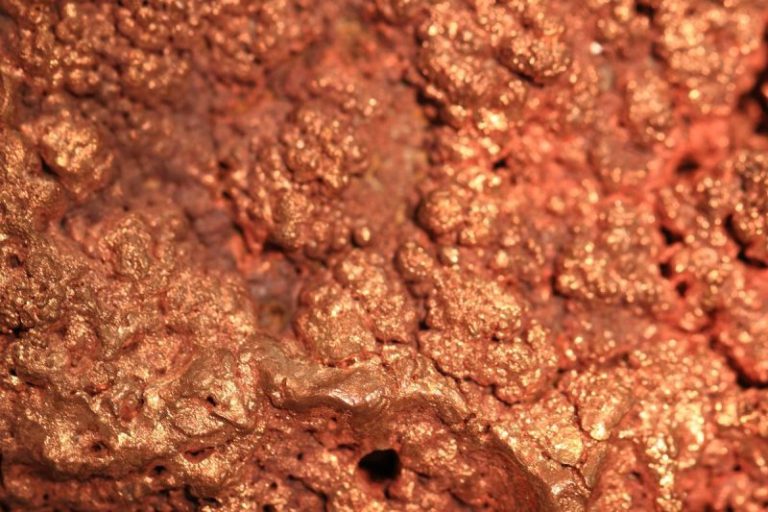

The first step in copper production is exploration to identify areas with potential copper deposits. Advanced technologies like satellite imagery, aerial surveys, and geophysical methods are employed to locate these deposits. Once a suitable site is identified, mining operations commence.

Mining of copper ore involves both underground and open-pit mining methods, depending on the depth and accessibility of the deposits. Underground mining involves tunnelling into the earth to extract the ore, while open-pit mining involves the removal of large quantities of ore from the surface.

2. Crushing and Grinding

Once the ore is extracted, it is transported to a processing plant where it undergoes crushing and grinding to reduce the size of the ore particles. This process facilitates the separation of copper minerals from the surrounding rock and other impurities.

3. Froth Flotation

After crushing and grinding, the ore is further processed using froth flotation, a method that exploits the differences in physical and chemical properties of minerals. In this process, chemicals are added to the ore to create a froth that selectively adheres to copper minerals, allowing them to be separated from the rest of the ore.

4. Smelting

The concentrated copper ore obtained from froth flotation is then subjected to smelting, a high-temperature process where the ore is heated in a furnace with fluxes such as silica and limestone. During smelting, the copper minerals are reduced to metallic copper, which is then cast into molds to form copper anodes.

5. Electrorefining

The final step in the process of refining copper involves electrorefining, where the impure copper anodes from the smelting process are placed into an electrolytic cell with a cathode made of pure copper. Passing an electric current through the cell causes copper ions from the anode to be deposited onto the cathode, resulting in high-purity copper cathodes that are ready for the market.

6. Market Distribution

The refined copper cathodes are then transported to manufacturers and fabrication plants where they are melted and cast into various products such as wire, tubes, sheets, and more. These products are used in a wide range of industries, including construction, electronics, and transportation, among others.

In conclusion, the process of mining and refining copper is a complex and multi-stage operation that involves exploration, extraction, crushing, grinding, flotation, smelting, and electrorefining. Each stage plays a critical role in producing high-quality copper products that are essential for modern society. By understanding the intricacies of copper production, we can appreciate the value of this versatile metal in our daily lives.